As a worldwide manufacturer of handcrafted makeup brushes, we understand the importance of quality raw materials in producing fine makeup brushes.

Not all material suppliers can provide the specific materials needed to achieve the desired results.

To this end, we have established facilities dedicated for raw material prcessing, giving us the ability to create tailor-made materials that fit production specifications.

With most materials needed for production, they are procured from our network of trusted suppliers with credible reputation of providing quality materials.

Our supplier list is meticulously filtered, ensuring we only get eco-friendly and safe materials that keep up with our brand ideals.

Raw materials go through an intensive inspection process before they are used to create our handcrafted makeup brushes.

Utilizing precision tools and years of experience, our manufacturing team goes over the materials to identify and filter out any defective or impure materials, keeping the end product top-class.

In order to maintain the high quality our makeup brushes are known for, our workers conduct an initial inspection process after every production step.

Some quality control checks include visual inspections to determine the look and feel of the bristles, along with strength and adhesion tests that show how the bristles tightly stick to the ferrule.

These self-inspection done by workers and full inspection done by QC team minimize the defect rate of the final makeup brushes.

XINXINLEI heavily invests on cutting-edge testing equipment to ensure every makeup brush sent out reflects the superior quality standards we have established.

Testing for oxidation levels that could result in rust if high, the ferrules are placed on a salt spray test machine and subjected to calibrated amounts of salt for 24 hours.

The makeup brush is placed inside a humidity and temperature test machine that gauges any change on the handle and glue materials on high or low temperatures.

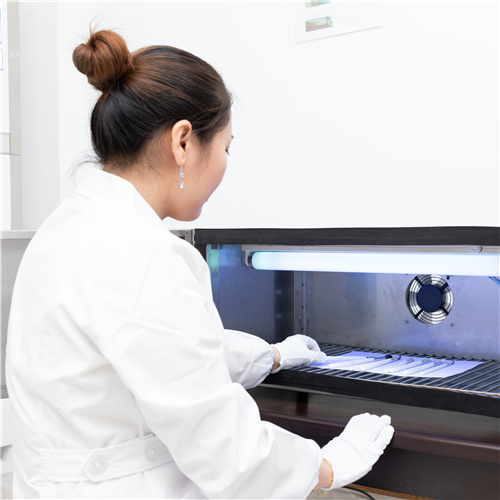

Makeup brush handles are tested using high-powered UV weathering test equipment to see if there will be any discoloration or yellowing when subjected to sunlight, ensuring the durability of makeup brushes.

With the help of modern vibration machines, the makeup brush and packaging go through simulated vibration tests to confirm the durability and firmness of both the makeup brush and packaging.

Using powerful adhesive tapes which are placed on the printed logo and then removed afterwards, we test the quality and adhesion of prints and logos on the makeup brushes.

To ensure the firmness of the handles, ferrules, and hairs, we use side shake test stands to pick out defective brushes that fall apart easily. It's also critical for us to optimize the glue for a more durable makeup brush.